Precise Robot Calibration with iMS – Highest Accuracy for Your Production

Precise Robot Calibration System for Maximum Manufacturing Accuracy

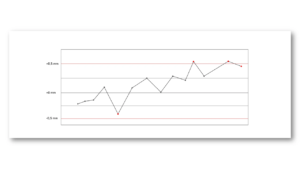

Modern industrial robots need to operate with millimeter precision to ensure consistently high production quality. Accurate robot calibration and precise TCP measurement are crucial to avoid positioning errors, scrap, and quality loss.

Why is Professional Robot Calibration Necessary?

Even the smallest deviations in robot kinematics can have serious consequences:

- Inaccurate component fittings

- Scrap due to faulty assembly

- Losses due to inaccurate workpiece positioning

Due to mechanical tolerances, temperature fluctuations, or collisions, the robot geometry changes over time. The solution is continuous robot calibration with our highly accurate iMS robot calibration system.

Robot Calibration Methods & TCP Measurement

There are various calibration methods to improve robot precision:

- Manual Calibration – via teach pendant or comparative measurements

- Contact Calibration – using touch probes for precise TCP measurement

- Optical Calibration – using camera systems, laser measurements, or non-contact sensors

Our iMS robot calibration system combines these methods to ensure maximum accuracy and long-term stable robot positioning.

iMS Robot Calibration System – Calibration 4.0 for Ultimate Precision

With our iMS calibration system, you optimize your robot calibration and increase process accuracy.

Advantages of iMS Technology:

- Automated TCP & Base Calibration – No manual adjustment required

- Increased Repeatability – Minimization of positioning deviations

- Fast Commissioning & Reduced Maintenance – Efficient robot processes with minimal downtime

- Reduction of Production Errors – Higher product quality & less waste

- Optimized Robot Replacement with Auto Teach-in – Seamless integration of new robots

With iMS, you can avoid robot failures, reduce calibration times, and increase overall equipment effectiveness (OEE).